Design for Manufacture (DFM)

Industry competition has forced companies to adopt technologies that would reduce cost and production time to deliver new product by utilizing existing resources and infrastructure. Design for Manufacturing is by far an answer to the above concerns. CAD Resource HQ, Inc. engineers focuses on reducing number of parts, standardization of parts, modular design, use of standard design features, and simplifying product design and keeping it symmetrical. The above concerns are met through Design for Manufacturing (DFM).

Our Design for Manufacture solutions are as follows:

- 2D drafts & 3D models of concepts are designed using latest CAD & FEA Analysis Software considering fits, function, clearances and tolerances, operating conditions, etc.

- FEA is carried out if necessary to evaluate design applying various loading conditions, alternatives are suggested and adopted.

- Material optimization to achieve reduced cost on inventory, usage of best material available which satisfies design requirement.

- Existing infrastructure with respect to jigs, fixtures and machineries are taken into consideration while offering the design solutions. Otherwise, products are designed such that they require simple tooling and manufacturing process.

- Tools and process optimization

- Confirming to safety, environmental, and various Industry Standards

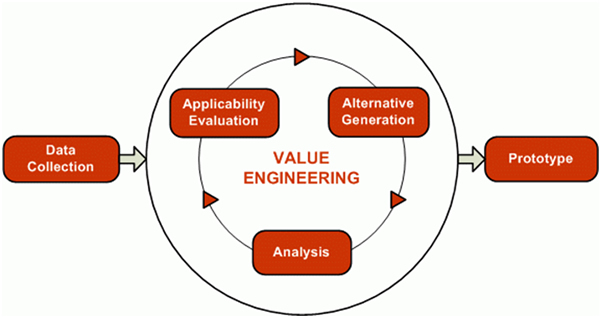

Value Engineering

Our experienced experts in value engineering will assist you with your value engineering needs at a very nominal cost. Our systematic value engineering process can significantly improve your functionality and at the same time reduce your costs. Apart from understanding the functionality of your product, our design engineers would apply a structured thought process whereby design constraints are considered, design variables are better understood, and the objectives for improvements that need to be carried out on the product are clearly defined. Our engineers apply the following basic steps for this process:

- Information gathering: They will evaluate your engineering process requirements for functionality and constraints.

- Alternative generation (Creation): They will examine various alternative ways of meeting your requirements and what else will perform the desired function

- Evaluation: They will assess all these alternatives and evaluate how well they meet the required functions with the amount of cost savings.

- Presentation: They will choose the best alternative and make final presentation to our customer for decision and approval.

Our value engineering experts utilizes their extensive experience in 3D CAD & FEA Analysis Software in delivering their final report.

The following products could be Value Engineered:

CAD Resource HQ, Inc. value engineering services can simplify your product design process and ease your manufacturing process. You can add value to the following:

- Products or machineries requiring automation

- Products requiring configuration changes to be delivered as variants

- Products requiring material and manufacturing process optimization, thus confirm to up to date standards and beyond

Reverse Engineering

CAD Resource HQ, Inc. valued customers can leverage from our technical expertise in Reverse Engineering (RE) to discover the technological details of a device, object or system through analysis of its structure, function and operation. Our reverse engineering services is driven by our constant urge to innovate. It is a “product to re-design” process, whereby the components and workings of an existing product are analyzed to create a superior and improvised design.

We utilize the following tools and software for Geometric Inspection:

- 3D Laser Scanner for Geometric inspection

- Rapidform XOV for manipulation of Point Cloud data

- Rapidform XOR for building up of Geometry

Our reverse engineering process is as follow:

- Each part is measured (based on the complexity of the part) either by conventional methods, CMM, sophisticated reverse engineering software or by white light scanning.

- These measurements which produce cloud point data are then converted into surfaces\lines or volumes.

- 3D models are then created, which are compared with physical products to ensure that all the information is captured, before generating 2D drawings for manufacturing.

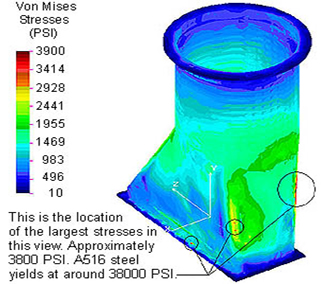

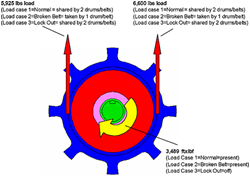

FEA Design Service

Engineers at CAD Resource HQ, Inc. are highly experienced in the use of Finite Element Analysis (FEA) to model a wide range of physical phenomena. As skilled development engineers, our contribution to your project rarely stops at the analysis output. We routinely work alongside with our customers to find realistic design solutions that offer genuine commercial benefits.;

Typical application of the FEA methods include Structural (stress, strain, deformation, fatigue), Thermal (Conduction, Convention and radiation), Dynamic (modal, harmonic, transient dynamic and rotor dynamic).

In recent years, FEA has become a powerful and versatile engineering tool enabling complex systems, for instance multi-part 3D assemblies, to be analyzed cost effectively. Non-linear and non-isotropic materials and surface-to-surface contacts are also routinely modeled.

In combination with our engineering design team and CAD & FEA Analysis Software, we have effectively integrated FEA into the design process, enabling rapid optimization before expensive product is manufactured.

Our structural engineers have great industry, standards, innovation, and extensive experience. We undertake conceptual, preliminary and detailed structural engineering design and analysis. While endeavoring to maintain international standards in quality, our structural engineering team strives to reduce product design cycle time as well as ensure cost effectiveness. We also support all phases of your structural engineering design process, from design, modeling, to analysis of new and existing components. Our team also has extensive experience in load bearing structures and support foundations for rotating equipments.

Our structural engineers have great industry, standards, innovation, and extensive experience. We undertake conceptual, preliminary and detailed structural engineering design and analysis. While endeavoring to maintain international standards in quality, our structural engineering team strives to reduce product design cycle time as well as ensure cost effectiveness. We also support all phases of your structural engineering design process, from design, modeling, to analysis of new and existing components. Our team also has extensive experience in load bearing structures and support foundations for rotating equipments.

We typically cover structures from and not limited to; steel and composite structures, beams and steel attachments, printing press facilities, steel production and allied industry, microwave antennas, equipment foundations, airport material handling and conveying systems, cement silos and aeration systems, etc.

2D & 3D Design & Drafting

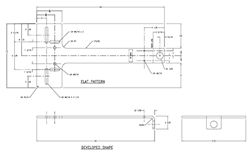

CAD resource HQ, Inc. 2D design and drafting is creation of accurate representations of objects for manufacturing and engineering needs. Our 2D drawings are used to fully and clearly define requirements for our customer’s concepts or products, and are usually created in accordance with standardized conventions for layout, nomenclature, interpretation, appearance, size, etc. Our 2D drafting has to essentially, accurately, and unambiguously capture all the geometric features of our customer’s product, thereby conveying all the required information needed to manufacture that product.

CAD resource HQ, Inc. 2D design and drafting is creation of accurate representations of objects for manufacturing and engineering needs. Our 2D drawings are used to fully and clearly define requirements for our customer’s concepts or products, and are usually created in accordance with standardized conventions for layout, nomenclature, interpretation, appearance, size, etc. Our 2D drafting has to essentially, accurately, and unambiguously capture all the geometric features of our customer’s product, thereby conveying all the required information needed to manufacture that product.

Our engineers, designers and drafters have extensive experience and expertise in CAD & FEA Analysis software. They also have diverse experience in Industry Standards as well as working with any custom in-house established standards by our customers.

Our 2D Design & Drafting includes:

- Orthographic, axonometric, perspective projections from 3D models

- 2D details from 2D or 3D assemblies or vice-versa

- Corrections to exiting 2D drawings involving change in standards or materials used in the manufacturing or fabrication details

- 2D or 3D exploded views of an assembly

- 2D manufacturing or fabrication drawings used in reverse engineering methodology on existing components

- BOM (Bill of Material)

- ECN or ECO (Engineering Change Notice or Order)

3D Modeling & Drafting

CAD Resource HQ, Inc. 3D visualization of models using CAD tools brings life and clarity into the design objectives with respect to interference, clearance, tolerance aspects, aesthetics; and helps communicate ideas more effectively. 3D modeling is the technical art of developing a mathematical, wire frame representation of any three-dimensional object. 3D models could be displayed as an image in print using a process called 3D rendering or used in a computer simulation.

CAD Resource HQ, Inc. 3D Modeling and Rendering include:

- Wire frame geometry creation

- 3D parametric feature based modeling, Solid modeling

- Freeform surface modeling

- Automated design of assemblies, which are collections of parts and/or other assemblies

- Validation/verification of designs against specifications and design rules

- Bi-directional parametric association (modification of any feature is reflected in all information relying on that feature; drawings, mass properties, assemblies, etc.)

- Kinematics, interference and clearance checking of assemblies

- Sheet metal

- 3D models/assemblies from 2D details/assemblies

- 3D sectional views

- 3D exploded assembly views

- 3D models using reverse engineering methodology

CAD & FEA Analysis Software

CAD Resource HQ, Inc. system requires no additional financial investment in technology from our customers. Our system can be easily integrated into our clients existing system and procedure. Our multi-disciplined and well-diversified staff works closely with our clients to accomplish their respective project goals. As a result of this effort, we are able to maintain a cutting-edge position enabling us to provide innovative as well as traditional solutions with superior service and support to our customers.

Our CAD Software includes but not limited to:

CAD Resource HQ, Inc. engineers and designers have expertise in the following software:

- AutoCAD

- Pro/Engineer

- Microstation

- Unigraphics

- SolidWorks

- Autodesk Inventor

- ANSYS

- STAAD Pro

- Autodesk Revit, etc.

Our FEA Software includes but not limited to:

CAD Resource HQ, Inc. engineers and designers have expertise in the following software:

- ANSYS

- Cosmos Works

- Nastran

- Q-Beam

- STAAD Pro

- ProSteel

- X-Steel

- X-Frame/P-Frame, etc.

Industry Standards

CAD Resource HQ, Inc. engineers, designers and drafters have extensive experience in the application of the following industry standards in their design and drafting processes:

- ASME

- AISC

- ANSI

- GD & T

- AWC

- OSHA

- MIL-STD

- ISO

- Six Sigma & Lean Manufacturing

- Imperial & Metric, etc.

Our engineering personnel can also work with our customers in-house established standards to meet their respective project needs.